Sheet Metal Process

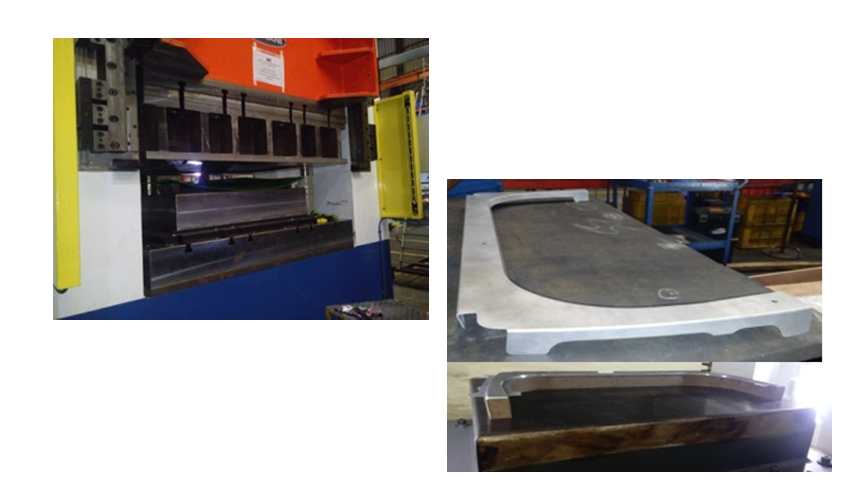

Tooling (Rubber Press Form Tools)

1000x100x1.0mm

1200x650x1.0mm

Nesting (with different Patterns)

Flat Blanks

Press load 1000 T applied for Rubber press forming

FLAT PATTERN / BLANK ROUTING CAPABILITIES

Almost 80% sheet metal structural parts have various bends and curve shapes. Before forming / stretching of Al Alloy sheet on the forming tool, it is required to develop Flat pattern and to be cut using routing method from the standard Al Alloy sheet. This flat patterns to be developed considering different geometrical features (Joggles, Bend angle, bend radius etc) on the part, sheet thickness and sheet holding areas. Our tool design team has expertise to provide correct developed flat pattern based on manufacturing process

Our Capabilities :

SHEET METAL FORMING CAPABILITIES

Sheet metal forming is a fundamental process in the metalworking that's generally used for low-volume production applications. It has been employed in aerospace production lines for many years to create various airframe and engine components. MRO will often produce one-off replacements for the repair of damaged vehicles and aircraft using metal forming. Rubber pad forming in which a ram forces through rubber pad pressing in aerospace production for shallow parts. Rubber pad pressing dies or form tools are traditionally CNC machined